Deciding which sound absorbing product to choose for a building used to be a fairly simple business. Assessing trade-offs between acoustic performance, design and budget were the primary considerations. But now we know that every product in a building has an additional cost for the indoor and outdoor environment. So it has become imperative that we look beyond the acoustics and take environmental impacts into account as well.

Accurately gauging environmental impacts

First on the list of ways to assess the impacts of a product should be an Environmental Product Declaration (EPD). Every company that cares about the emissions created by their products will have easy-to-access, easy to read EPDs – at least for those products which constitute the majority of their sales.

Good EPDs include emissions from:

- Raw materials and manufacturing (life cycle stages A1-3),

- Transportation, installation and energy usage (life cycle stages A4-5),

- Use, such as maintenance and repair (life cycle stages B1-7),

- End of life stages of a product, where the product enters various waste streams depending on how it is handled (i.e. life cycle stages C1-4), and

- Reuse/recovery/recycling potential, the stage in which where the circularity potential of the product is assessed (life cycle stage D).

What is most important in an EPD?

Since this is a lot of information to process, EPDs summarize environmental impacts in a number of main categories. The most relevant value for sound absorbing materials is “global warming potential”, which summarizes in kg the amount of greenhouse gases (including C02) that the product has produced across all of the life cycle stages assessed. Although it does not tell the whole story, it is a fairly simple metric for comparing performance and environmental harm across a range of products.

A practical example

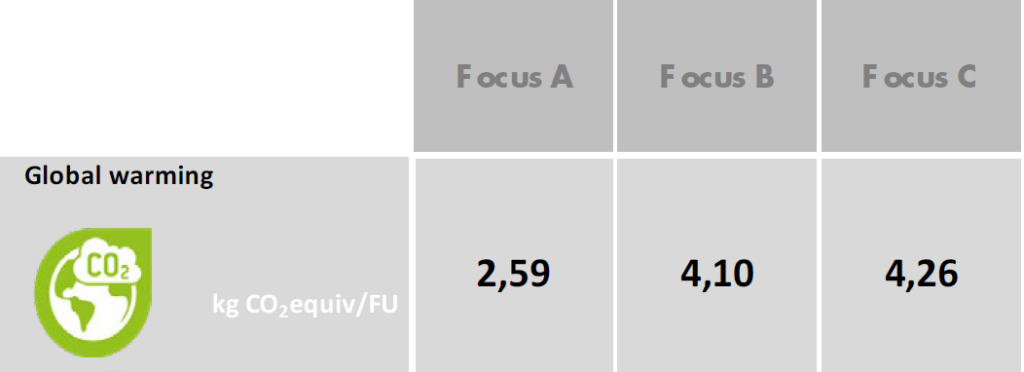

Below you can see an excerpt from the summary table of the EPD for a 20mm glasswool panel as an example (download the full EPD here). This summary value indicates kg C02 equivalent (equivalent means that it includes other harmful gases as well) for each “functional unit” – in this case the functional unit is per square meter.

The environmental cost of Focus A, in terms of greenhouse gas emissions, is 2.59 kgCO2equiv per square meter. In this specific case, the differences in kgC02equiv between Focus A, B and C are due to the complexities of manufacturing different edges.

When comparing with other products, different types of surface as well as levels of acoustic performance will have different implications for the environment. Tradeoffs between acoustic performance, design requirements, budget, client needs and environmental impacts should be fully taken into account before making the right decision.

A word on materials

A primary factor influencing the sustainability of a product are the materials, since the majority of greenhouse gas emissions are produced during life cycle stages A1-3 (raw materials and manufacturing). Ensuring that the materials have a high degree of recycled content is a primary way of keeping emissions to a minimum in these stages and is something to look out for in a mineral wool product.

For example, the raw materials that make up the sound-absorbing part of a Focus A panel consists of 70% recycled glass bottles and jars. Glass wool can also be made from mixing limited raw materials such as sand, limestone and soda ash. As a result, not all mineral wool is created equal. Manufacturers that utilize high proportions of waste materials have already made an active commitment to sustainability by investing in circular manufacturing processes.

What’s next?

The next step for any responsible recommendation to be made is to compare emissions across products and across manufacturers, in order to make the right choice for both the sound environment and the ecosystem.

Some suppliers of acoustic materials do not have EPDs for their products. In which case, the question should be: “why?”. All responsible manufacturers have long ago made commitments to Net Zero emissions by 2050, and the road to Net Zero begins with simple measurement as a first step. Emissions can only be reduced once we know what they are.

Finally, EPDs are not standardized yet. For example, some EPDs will have different functional units, so a responsible acoustician or architect might be falling into the trap of comparing apples with pears by comparing a product’s emissions per kg with emissions per m2 of another. That’s why we are advocating for an industry-wide move to standardized EPDs for every product. Until that happens, the devil is in the details. A responsible specifier will need to become adept at reading the fine print and establishing a baseline knowledge of environmental reporting.

Where can I find more information?

Read more about how what to expect from EPDs here and learn more about how to compare them here.

Access Ecophon’s download centre here to see our full range of EPDs covering 85% of our product sales to date (March, 2023).

Please visit the Sustainability section of our website here and learn more about our goals for reducing our emissions by 2025, 2030 and 2050. For any additional information about sustainability at Ecophon, please contact [email protected].

Text: Douglas MacCutcheon, PhD. Global Concept Developer for Sustainability at Saint-Gobain Ecophon.